Consider the hazards the wearer will face in the work environment when choosing summer composite shoes

The first thing to consider when choosing summer composite shoes is the hazards to which the wearer will be exposed in the working environment, but in general, summer composite shoes must be soft, moisture-resistant, moisture-absorbent and sweat-absorbent, as well as the features listed below.

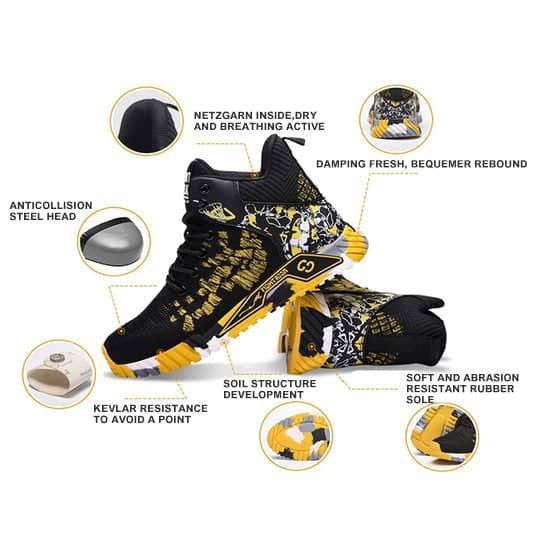

Soles

For different working environments, the material and pattern of the sole can be designed to increase friction and have a better effect on slip resistance; the sole can also be made to be shockproof, anti-static, insulating, heat and oil resistant.

Smash-proof

When objects fall or collide on the work site, the toe guard can be used to prevent heavy and sharp objects from hitting the shoe. The requirements must meet the requirements of Steel Toe rated ASTM F2412/2413-2011 I/75 C/75 for protection, standards protective >200J.

Electrical insulation

Electrically insulated footwear is a protective shoe that insulates the feet from live objects and prevents electric shocks. They must meet the requirements of Electrical Hazard (EH) - ASTM F2892-11-tested for safety.

Puncture prevention

Puncture protection is available when there is a risk of nails, metal scraps or other sharp objects cutting into the soles of the feet, and must meet ASTM F2413-18 standards.

Anti-static

Anti-static shoes must be able to eliminate the build-up of static electricity in the human body and prevent electric shock from power sources below 250V, and must take into account the insulation of the sole in order to prevent the danger of induction or electric shock.

The uppers of summer slip on work shoes are made of rubber or PVC to prevent water penetration, but when summer slip on work shoes are made of such materials, they are not breathable and make the wearer feel uncomfortable and unhygienic. There are now materials that prevent water penetration but allow air in and out, making them more comfortable and hygienic for the user, but relatively expensive. They are usually made from genuine leather and have good breathability.

Summer slip on work shoes are worn on the feet, in contact with the ground, is an important way to discharge static electricity in factories and workshops, summer slip on work shoes are not disposable products, but can be used many times, in order to ensure the performance and cleanliness of summer slip on work shoes, they need to be cleaned often, but the cleaning method of summer slip on work shoes and general footwear is not the same, cleaning Improper cleaning can also cause damage to the shoe.

No long soaking

In general, in order to clean shoes, we soak them in water for a while so that the stains can be removed more easily, but summer safety shoes have leather and fabric uppers, so there are different cleaning methods.

Don't use acidic chemical solvents

Don't use acidic or alkaline chemical solvents to clean your summer safety shoes, as this can easily discolour or distort them.

Do not use high temperature washing

Summer safety shoes should not be washed with high temperature, the temperature should not be too low, high and low temperature will damage the fiber tissue of summer safety shoes, so that the performance of summer safety shoes is reduced, the washing temperature of summer safety shoes is about 40 ℃.

After using detergent, rinse with plenty of water to prevent residual detergent. After washing, do not put them in the sun directly, but choose a cool and ventilated place to dry.

Soles

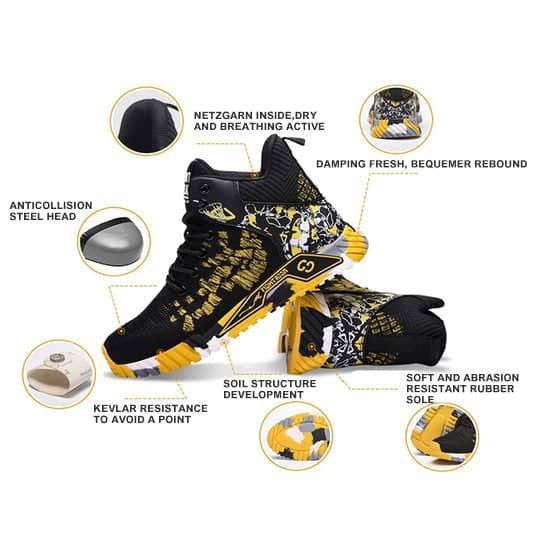

For different working environments, the material and pattern of the sole can be designed to increase friction and have a better effect on slip resistance; the sole can also be made to be shockproof, anti-static, insulating, heat and oil resistant.

Smash-proof

When objects fall or collide on the work site, the toe guard can be used to prevent heavy and sharp objects from hitting the shoe. The requirements must meet the requirements of Steel Toe rated ASTM F2412/2413-2011 I/75 C/75 for protection, standards protective >200J.

Electrical insulation

Electrically insulated footwear is a protective shoe that insulates the feet from live objects and prevents electric shocks. They must meet the requirements of Electrical Hazard (EH) - ASTM F2892-11-tested for safety.

Puncture prevention

Puncture protection is available when there is a risk of nails, metal scraps or other sharp objects cutting into the soles of the feet, and must meet ASTM F2413-18 standards.

Anti-static

Anti-static shoes must be able to eliminate the build-up of static electricity in the human body and prevent electric shock from power sources below 250V, and must take into account the insulation of the sole in order to prevent the danger of induction or electric shock.

The uppers of summer slip on work shoes are made of rubber or PVC to prevent water penetration, but when summer slip on work shoes are made of such materials, they are not breathable and make the wearer feel uncomfortable and unhygienic. There are now materials that prevent water penetration but allow air in and out, making them more comfortable and hygienic for the user, but relatively expensive. They are usually made from genuine leather and have good breathability.

Summer slip on work shoes are worn on the feet, in contact with the ground, is an important way to discharge static electricity in factories and workshops, summer slip on work shoes are not disposable products, but can be used many times, in order to ensure the performance and cleanliness of summer slip on work shoes, they need to be cleaned often, but the cleaning method of summer slip on work shoes and general footwear is not the same, cleaning Improper cleaning can also cause damage to the shoe.

No long soaking

In general, in order to clean shoes, we soak them in water for a while so that the stains can be removed more easily, but summer safety shoes have leather and fabric uppers, so there are different cleaning methods.

Don't use acidic chemical solvents

Don't use acidic or alkaline chemical solvents to clean your summer safety shoes, as this can easily discolour or distort them.

Do not use high temperature washing

Summer safety shoes should not be washed with high temperature, the temperature should not be too low, high and low temperature will damage the fiber tissue of summer safety shoes, so that the performance of summer safety shoes is reduced, the washing temperature of summer safety shoes is about 40 ℃.

After using detergent, rinse with plenty of water to prevent residual detergent. After washing, do not put them in the sun directly, but choose a cool and ventilated place to dry.